We are mechatronics professionals from

the semicon manufacturing site.

We are mechatronics

professionals from

the semicon manufacturing site.

-

Philosophy

Delight customers with our automation

-

Challenge

Through the technology fusion of mechatronics and robotics,

we provide respond to customer requirement for automation of manufacturing site. -

Industry

Try new industries with our experience

in semiconductor and electronics industry -

Achievement

40 years, over 5,000 units installed,

rich experience

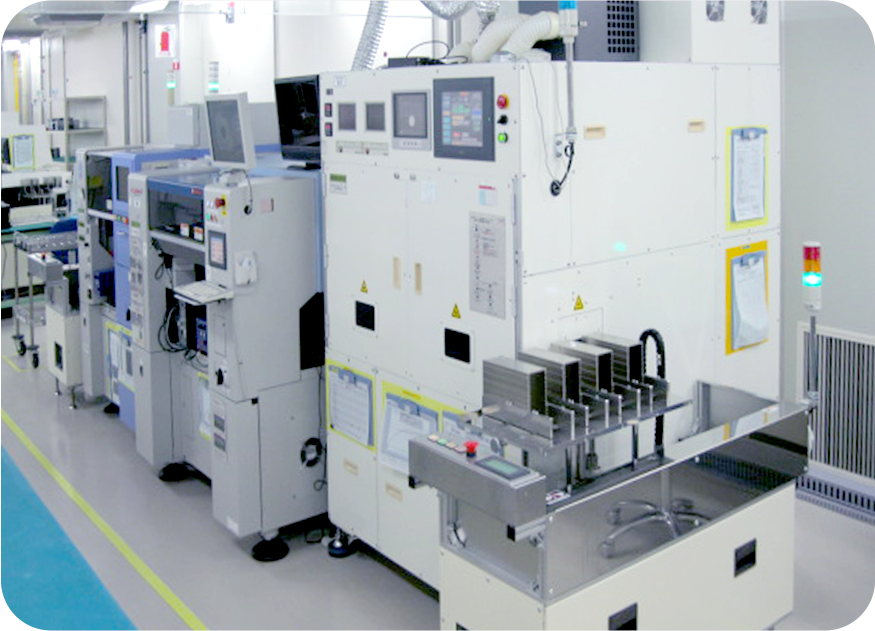

With our enriched experience in the semiconductor industry,

we provide the best solution for automation in your manufacturing site.

With our enriched experience

in the semiconductor industry,

we provide the best

solution for automation in

your manufacturing site.

I would like to improve productivity, stabilize quality, improve safety,

prevent individualization, save labor, etc.

-

POINT 01

Equipment concept

proposal -

POINT 02

Matching required

specifications -

POINT 03

Development /

manufacturing /

assembly -

POINT 04

After sales

service

*Examples of custom-made equipment will not be disclosed due to the contract with the customer.

Examples

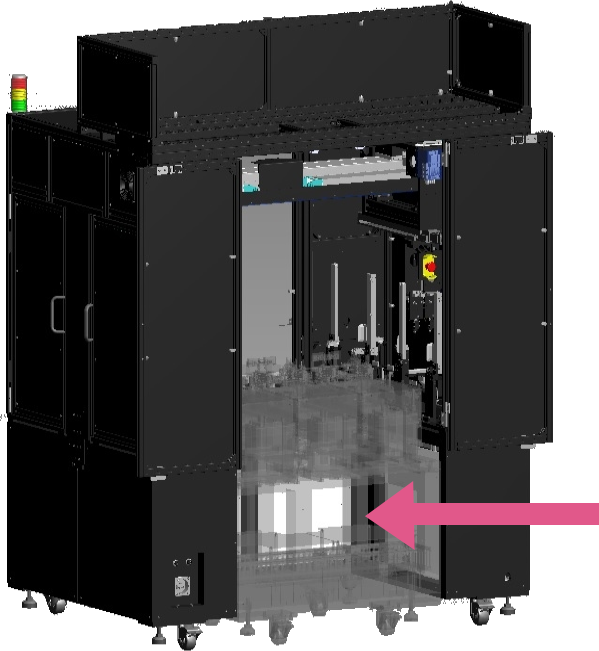

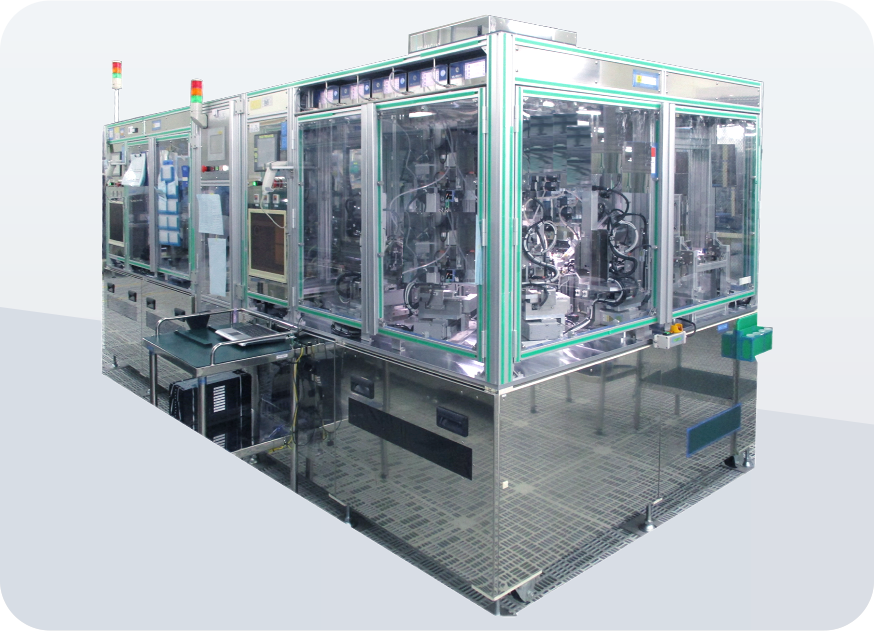

Customized test handler DX series

This is a fully automatic test handler with a structure in which the transport unit and the inspection unit are separated.

We can also offer various test units according to the inspection contents of the camera module.

Actual applications of

Actual applications of

test units

We customize the test unit according to the work and inspection environment of the customer.

-

DX1533 For the downward characteristic inspection of camera module

- 3 Stage (6dut) type

-

Test unit

infinity characteristic inspection / black scratch inspection / white scratch inspection

-

DX1327 For the stroke behavior measurement of camera module

- 3 Stage (6dut) type

-

Test unit

VCM stroke inspection / OIS (optical image stabilization) characteristic inspection

-

DX2299 For ultra wide-angle camera module

- 2 Stage (4dut) type

-

Test unit

Optical center inspection / black scratch inspection

FEATURE

FEATURE

-

It is possible to configure

the test unit according

to various objects

and inspection contents. -

The other packages

would be proposed

after consultation.

(CSP / BGA / QFN / QFP, etc.)

- Uniformalized object conveying section

- Handler shape W1760 x D1230 x H2280 (mm)

- Test unit dimension: W 940 x D700 x H1000 (mm)

-

Processing capacity: 300 - 500 (UPH)

*This varies depending on the test unit and inspection details.

Other equipment

-

Camera module fully

automatic tester -

General-purpose loader /

unloader -

Laser solder

mounting equipment -

Inline multifunction resin coating machine